Gary Ades on Food Safety: HACCP! HACCP! HACCP! - PART 1

So much has been written about HACCP (Hazard Analysis Critical Control Point, pronounced "Hassip"), that it is difficult to know where to start. While many of you have no doubt been exposed to HACCP and may use it in your everyday activities, others still require background information. So as not to bore either group, I will try to share background information with you for the novice and provide insights based on over 25 years experience that we at Technical Food Information Spectrum, Inc. have had with HACCP.

Contrary to popular belief, in some cases, HACCP does not mean, "Have a cup of coffee and pray "(a quote that was supposedly attributed to an inspector). It is truly a common sense approach to Food Safety that minimizes risks but does not provide zero risks. HACCP has often caused confusion, many times because it has been made to be far more complicated than it is. If you were running a manufacturing facility, preparing, selling or distributing food in a safe manner, you were probably doing many of the things that HACCP defines. You probably were not doing them according to the specific Seven Principles of HACCP, nor were you being intimidated by the name. But HACCP is now the law for manufacturers of meat and poultry items and seafood; proposed for juices and produce; and defined for retail establishments in the 1999 Food Code and in "Managing Food Safety: HACCP Principles Guide for Operators of Food Service, Retail Food Stores and Other Food Establishments at the Retail Level" - (FDA, April, 15, 1998).

The group that has had a significant impact on defining HACCP in the US is the National Advisory Committee on the Microbiological Criteria of Foods (NACMCF). The latest document that describes their recommendations is entitled "Hazard Analysis and Critical Control Point Principles and Application Guidelines", August 14, 1997. The international organization that prepared the CODEX Alimentarius also describes HACCP in their 1997 text entitled, "Food Hygiene Basic Texts". The two documents essentially provide for the same activities.

HACCP is a systematic approach to designing a plan and running a system to control food safety hazards in a food process. The HACCP concept supports a producer's, manufacturer's, foodservice operator's, retailer's, or distributor's goal to supply safe food – one that will not cause illness or injury to a consumer when used as intended.

A suitably written HACCP Plan accommodates changes in processing procedures, equipment function or design, or the introduction of a new or different ingredient in the overall product formulation or recipe. HACCP can be applied throughout the food chain from primary producer to final consumer (farm to fork, pond to pan, orchard to oven, grunt to gut, etc.)

HACCP is a systematic, two-part process used to:

1) Assess hazards, taking into consideration factors that contribute to most outbreaks and risk evaluation techniques to identify and prioritize hazards.

2) Identify control measures that focus on prevention, establishing controls to reduce, prevent, or eliminate safety risks.

HACCP is preventive, not reactive. Its goal is to prevent hazards at the earliest point in the food production chain. The system, when properly applied, can be used to control any area or point in the food system that could contribute to a potentially hazardous final product. HACCP should be utilized in conjunction with other food protection programs, such as Good Manufacturing Practices (GMPs), Good Agricultural Practices (GAPs), Standard Operating Procedures (SOPs), and Prerequisite Programs (Sanitation, Facility and Equipment Design, Allergen Control, Glass Control, Preventive Maintenance, Training, Employee Hygiene, Pest Control, Supplier Selection and Approval, Product Tracking, Recall, Crisis Management, etc.).

In order to apply HACCP successfully, a firm must develop a different viewpoint or create "new eyes." For many, HACCP changes the thought process from concern over sanitation procedures and inspection of end products to prevention of food safety risks and control of processes. HACCP requires a strong management commitment to food safety and personnel education and training. Understanding the reasons for performing an action or a procedure becomes an integral part of an effective HACCP program.

The concepts of HACCP originated from work done in the 1960's to help establish the risk of salmonella in food. The work was performed by the U.S. National Aeronautics and Space Administration (NASA) and the U.S. Military Natick Laboratory. HACCP as it is known today took form at the 1971 National Conference on Food Protection, where risk assessment was combined with the critical control point concept. The Pillsbury Company first used HACCP in the manufacturing of food intended for the U.S. Space Program. Dr. Howard Bauman, then of the Pillsbury Company, led the effort to successfully employ the HACCP System for space food safety.

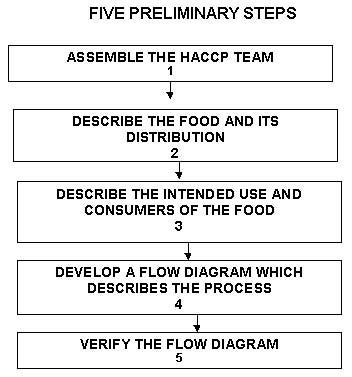

As defined by the NACMCF and CODEX, HACCP has five (5) Preliminary Steps and seven (7) Principles.

Preliminary Steps Leading to the Development of a HACCP Plan

1. Assemble the HACCP Team – The HACCP team is extremely important to the success of the HACCP system. While an experienced individual can successfully analyze hazards and implement a HACCP Plan, some important points might be missed or misunderstood when the "team" approach is not used.

It is the Team's responsibility to develop each step of the HACCP Plan. Beginning with the preliminary step and continuing through all Seven Principles, the Team develops, writes, verifies, and implements the HACCP system. When necessary, the Team calls in scientific or technical expertise to resolve problems. Finally, since the daily operations of a plant, retail operation, or distributor does not always remain the same, the team must conduct frequent verifications and modify the Plan accordingly.

2. Describe the Food and its Distribution – A complete description of the food product made within the facility and the method of distribution (frozen, fresh, common carrier, ice, etc.) should be written.

A description of the food includes its raw ingredients, formulation, preservation system, packaging, etc. A description of the method of distribution includes type of transport and any special consideration to maintain product safety.

3. Identify Intended Use and Consumers – The intended use is the expected use by the targeted consumer. Describe how the product is to be used, indicate if it is to be fully cooked by the consumer, what preparations will be needed by the consumer, what are the serving requirements, etc. Identify the targeted consumer, indicate if the consumer is the average retail shopper, a foodservice organization, or if the consumer has special considerations as infants or geriatrics.

4. Develop the Flow Diagram – Provide a clear, simple description of the process steps. Include all steps under the facility's control even optional steps such as re-pack. If desired, add steps before and after the process outside of the facility's immediate control. This flow diagram should be complete so that those who are unfamiliar with the process can follow the process using the flow diagram. The HACCP Team will use the flow diagram to complete the rest of the HACCP Plan.

5. Verify the Flow Diagram – The HACCP Team conducts a walk through of the facility with the flow diagram to check for accuracy and completeness. In addition, there should be others familiar with the process review it. It should be modified as necessary.

Once these preliminary steps are completed, the team is ready to conduct the Hazard Analysis, which is the first of the Seven HACCP Principles.

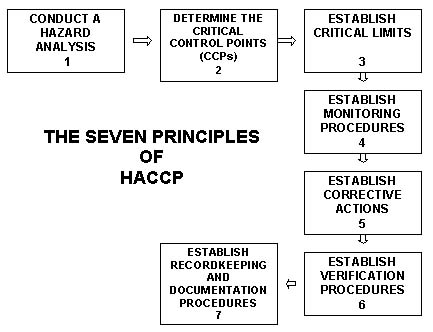

Overview of the HACCP Principles

The NACMCF defines HACCP as a systematic approach to be used in food production as a means to assure food safety. HACCP systems must be developed by individual producers, operators, retailers and distributors and tailored to their individual food production, processing, packaging, distribution and retail requirements. While the principles of HACCP can apply to all hazards associated with food production, the NACMCF recommends against the use of HACCP for reasons other than assurance of food safety.

The purpose and the principles stated by the NACMCF are:

PURPOSE: HACCP is a systematic approach to food safety consisting of Seven Principles:

In HACCP! HACCP! HACCP! – Part 2, I will discuss each of the Seven Principles and their challenges, the significance of hazards and the role that significance plays in a company's risk based decision-making process.

Gary Ades, Ph.D, is president of Technical Food Information Spectrum, Inc. (TFiS), a leading food safety and quality consulting firm. Dr. Ades is a professional food scientist and consultant with over 25 years of experience in the food industry. For more information, Dr. Ades can be reached at 800.248.8347 or via E-mail at tfis@ix.netcom.com.